CORPORATE GOVERNANCE

STATEMENTS

32

CITIC ENVIROTECH LTD.

Annual Report

2015

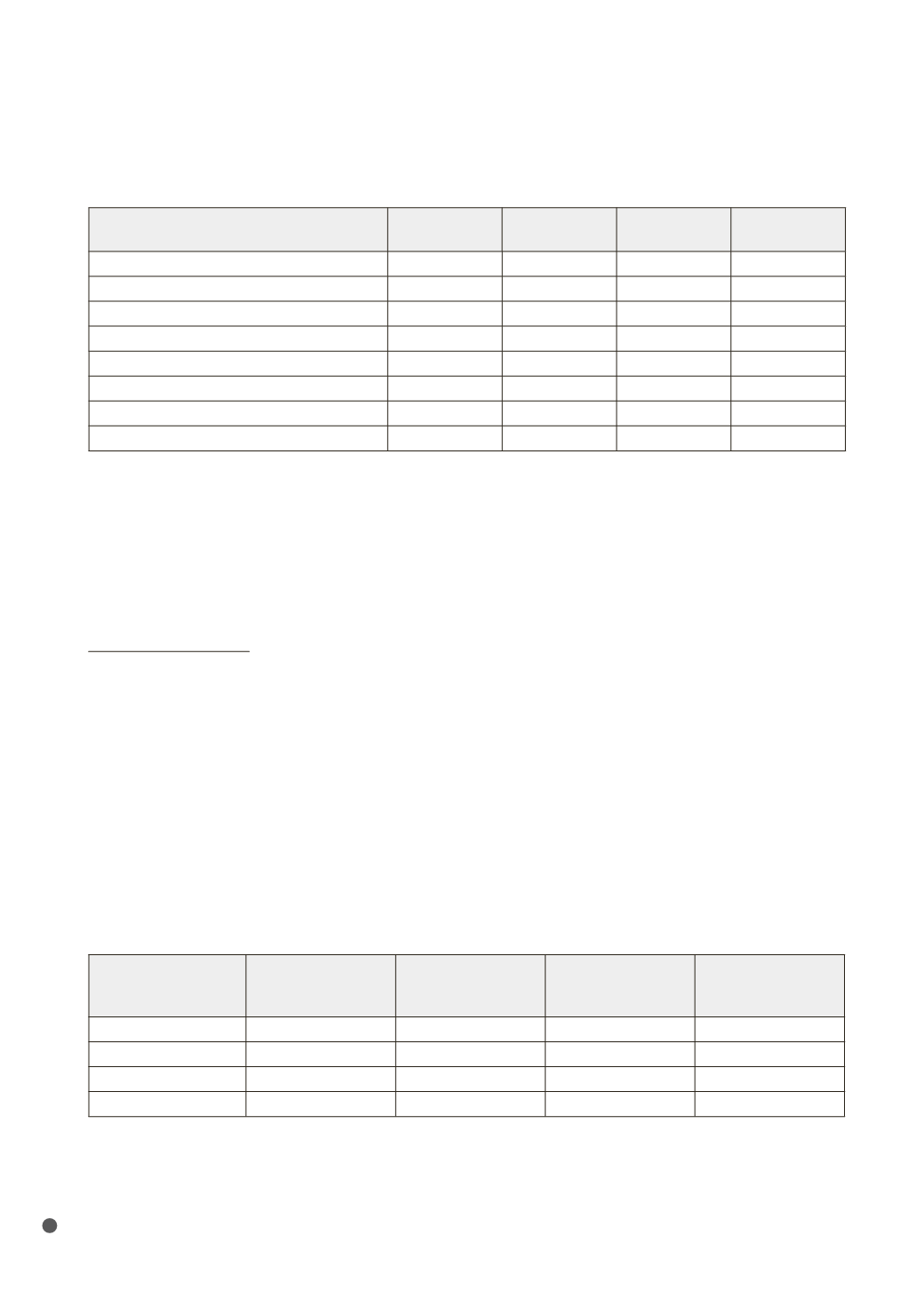

FY2012-13 FY2013-14 FY2014-15

Apr-Dec 2015

(9 Months)

Total Employee Work Hours

1,106,404

1,738,936

2,606,492

2,571,232

Total Contractor Work Hours

1,354,263

1,653,540

2,533,124

1,001,645

Cases of Occupational Illness

0

0

0

0

Cases of Employee Workplace Injuries

1

3

1

2

Cases Contractor Workplace Injuries

1

2

1

0

Number of Fatality (Employee)

0

0

0

0

Number of Fatality (Contractor)

0

0

1

0

Number of Work Days Lost (Employee)

0

183

0

4

During June 2015, in line with the China State Administration of Workplace Safety’s safety month

promotion, all operation teams in CEL implemented safety campaigns. Activities included emergency

drills, fire prevention, risk reviews, health screenings, safety quizzes and training. In response to the China

government’s call to improve chemical safety after the 12 August 2015 explosion in Tianjin, we carried out

safety practices review of project and plant sites in China, Singapore and Malaysia. As a result of the review

and feedback from operation teams, throughout October till December, we implemented standardisation

of personal protective equipment, safety signage as well as improved inventory monitoring of chemical

consumption.

Environmental Impact

Our single most important contribution to making the environment better is our core business – turning

polluted water into clean water, which is either safe for the receiving water bodies or reclaimed for suitable

applications. As at December 2015, our people operate and maintain 39 treatment plants (Note: Number

of treatment plants does not equate to number of business entities), with average volume of 1.11 million

m

3

/day (Note: Actual treated volume does not equate to volume generating income due to different

structure of concession agreements for various facilities). This is an average daily volume increase of 29%

from March 2015, when we operated 32 plants. In terms of absolute volume increase, this does not appear

to be a big number.

However, as the increase is mainly from industrial trade effluents, the wastewaters are more concentrated

(polluted) and require more effort in treatment (and therefore generate more revenue). During the period

from April to December 2015, industrial wastewater contributed to nearly 60% of our recurring income. In

the previous reporting period from April 2014 to March 2015, industrial wastewater contributed 47% of our

revenue from treatment plant operation.

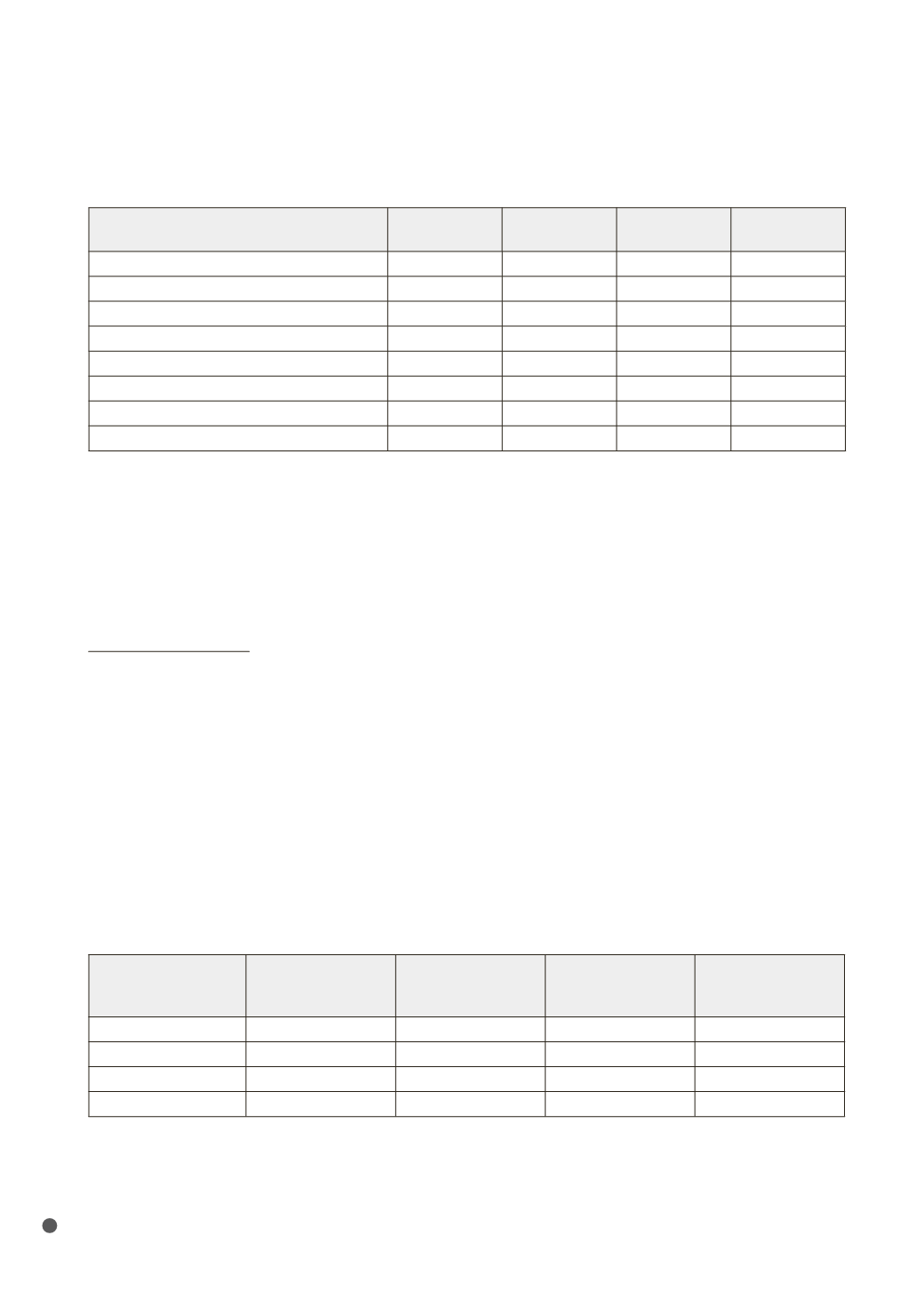

Reporting Period

No. of Plants

Operated

Total Volume of

Treated Water

(Million m

3

)

Specific Energy

Consumption

(kWh/m

3

)

Revenue from

Water Treatment

(Million RMB)

April to Dec 2015

39

305

0.39

488

FY 2014 – 15

32

315

0.34

528

FY 2013 – 14

26

294

0.26

392

FY 2012 – 13

15

211

0.24

256

We are continuing our focus to increase our portfolio in industrial effluents, to leverage our strength in

innovative engineering design, application of membrane and R&D capability. Compared to municipal

wastewater, industrial trade effluents are more complex in characteristics, and vary from one trade

to another. Our design and R&D teams are able to take these problems into the laboratories and bring

effective field solutions to our clients.